-

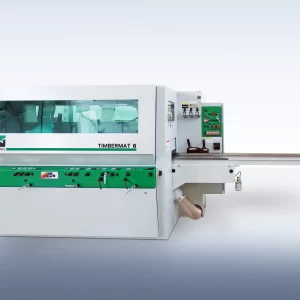

Weining Timbermat 6 – Planer & Moulder

WEINIG uses only high-quality components. Such as the heavy base of high-quality cast iron. In comparison to steel, cast iron has very high vibration reducing properties and is the material of first choice when mass and weight are needed.

Balance is the key

Experienced specialists demand a perfect distribution of strength and weight. By using special calculation

programs, we continuously optimize the WEINIG base. With optimum results: WEINIG machines generate the best surfaces by far in the solid wood processing industry. -

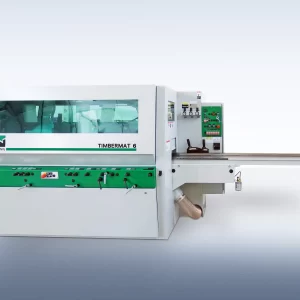

Weining Timbermat 5 – Planer & Moulder

WEINIG uses only high-quality components. Such as the heavy base of high-quality cast iron. In comparison to steel, cast iron has very high vibration reducing properties and is the material of first choice when mass and weight are needed.

Balance is the key

Experienced specialists demand a perfect distribution of strength and weight. By using special calculation

programs, we continuously optimize the WEINIG base. With optimum results: WEINIG machines generate the best surfaces by far in the solid wood processing industry. -

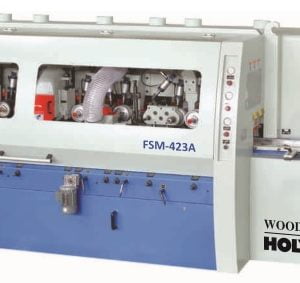

JAI Four Side Moulder J-4423

Width, Thickness & Shape in one pass.Thus Cost Effectively enhancing productivity

- Sturdy built heavy-duty machine to suit Indian working condition for precise application of four side operation in one pass.

- Use for mass production of door frames, window frames,wooden floors.etc.

- Separate motors for each spindle to ensure efficent power transmission.

- Powerfull drives for the cutter blocks delivers high torque for heavy duty cutting requiremens.

- Top feed rollers for easy feeding of work piece with variation in thickness.

- Bed lubrication to reduce friction and improve feeding of timbers.

- Sealed safety enclose to reduce noise levels, improve extraction and operator safety.

-

JAI Four Side Moulder J-4230

JAI Four Side Moulder J-4230

Sturdy built heavy-duty machine to suit Indian working condition for precise application of four side operation in one pass.

Use for mass production of door frames, window frames,wooden floors. etc. Separate motors for each spindle to ensure efficent power transmission. Powerfull drives for the cutter blocks delivers high torque for heavy duty cutting requiremens.

Top feed rollers for easy feeding of work piece with variation in thickness. Bed lubrication to reduce friction and improve feeding of timbers. Sealed safety enclose to reduce noise levels, improve extraction and operator safety.Standard Accessories

- 04 no’s ele. motors of 5HP / 2800 RPM,

- 03 no’s gear box with 0.5 HP / 1440 RPM ele. motors, Control Panel

- Lubrication pump

- Toolkit & m/c manual.

-

Woodmizer 4 Sided Planer and Moulder MP360

The MP360 four-sided planer/moulder is a high-production, large capacity machine engineered for professional workshops. With a larger capacity and higher hourly production levels than the popular Wood-Mizer MP260 planer/moulder, the MP360 planes and moulds boards on all four sides in a single pass into a variety of professionally finished products.

The MP360 planer/moulder has four cutting heads with the ability to produce single, two, three, and four-sided final products in various profiles. The MP360 has user-friendly measurement scales with a large 13 3/4? (350mm) wide x 6? (150 mm) high capacity for four-sided planing/moulding. The capacity for one-sided planing is 20? (510mm) x 9? (230 mm) and two-sided planing/moulding is 16 1/8? (410 mm) x 9? (230 mm). For two-sided planing/moulding, the table and machine height are adjusted together from 3/8?- 9? (10 ? 230mm) to precisely align and optimize material entering the machine.

A centralized control panel allows the operator to start and stop the chip extraction system, four cutter motors, and power feed motor separately. With the same 4HP (3kW) vertical cutter motors as the MP260, the MP360 features more powerful 7.5HP (5.5kW) top and bottom horizontal cutter motors for increased production. Four steel and one polyurethane power roller steadily move the board through the machine to ensure a consistent profile from end to end even with uneven boards. The feed rate is faster than the MP260 and adjustable from 10 ? 49 ft/minute (3-15 m/minute) to efficiently process both softwood and hardwood material.

Categories