Sold By:

Shreepal

In stock

To cool the glue joint and statically discharge the edging material

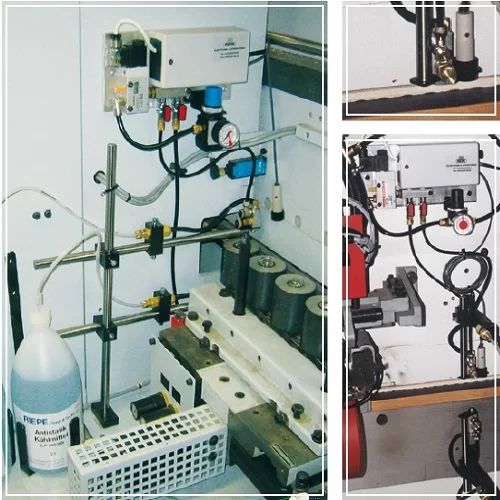

The perfect addition to the release agent spraying unit fitted at the machine infeed and the cleaning agent spraying unit fitted at the end of the machine is the antistatic-coolant unit shown in the adjacent photograph. It can be fitted downstream of the last contact pressure roller, upstream of the cross cut saws or upstream of the radius milling stations.

The antistatic-coolant LP289/99? is sprayed directly on the glue joint and on the edging material by means of our spraying units.

As a result the glue joint surface is hardened. The glue buildup on the tools is notably reduced and consequently the glue is no longer transferred onto the edging material. Furthermore, the edging material is statically discharged. Tracer rollers and workpieces remain free from milling chips.

Milling off (flush trimming) the PVC or PP edges causes static charging of the edging material and the adjoining top and bottom face of the workpieces.

Milled off chips adhere to the edging material and on the top and bottom surface of the panel negatively impairing the

function of the tracer rollers and making a precise finishing by scraper blades or milling impossible.

This unit remedies the above problems instantly !!

SKU:

WZSHREPAL012

Categories: Chemicals, Cleaning Agents, Materials, Spraying Unit

To cool the glue joint and statically discharge the edging material

The perfect addition to the release agent spraying unit fitted at the machine infeed and the cleaning agent spraying unit fitted at the end of the machine is the antistatic-coolant unit shown in the adjacent photograph. It can be fitted downstream of the last contact pressure roller, upstream of the cross cut saws or upstream of the radius milling stations.

The antistatic-coolant LP289/99? is sprayed directly on the glue joint and on the edging material by means of our spraying units.

As a result the glue joint surface is hardened. The glue buildup on the tools is notably reduced and consequently the glue is no longer transferred onto the edging material. Furthermore, the edging material is statically discharged. Tracer rollers and workpieces remain free from milling chips.

Milling off (flush trimming) the PVC or PP edges causes static charging of the edging material and the adjoining top and bottom face of the workpieces.

Milled off chips adhere to the edging material and on the top and bottom surface of the panel negatively impairing the

function of the tracer rollers and making a precise finishing by scraper blades or milling impossible.

This unit remedies the above problems instantly !!

Additional information

| Model Number | Antistatic-Coolant Agent LP 289/99? |

|---|---|

| Usage | NA |

| Dimension(L*W*H) | NA |

| Net weight | NA |

| Material | NA |

| Load capacity/Life Cycle | NA |

| Power(W) | NA |

| Thickness | NA |

| Voltage | NA |

| Speed | NA |

| Delivery Detail | Delivered and installed by manufacturer. Cost on actuals. |

Brand

Riepe

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.