In stock

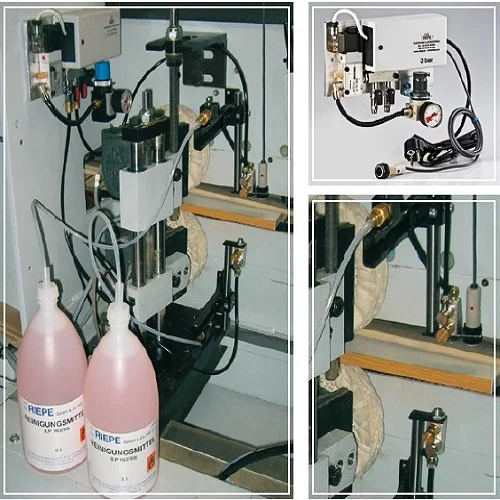

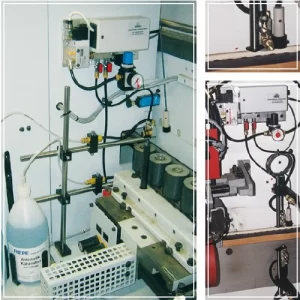

This unit is used to spray the cleaning agent LP163/93? on the top and bottom surface of the board edge, as well as the edgeband. The release agent applied at the machine infeed side and the loose glue residue are removed by the application of the cleaning agent and subsequent buffing.

Furthermore, the glue joint and the edge banding are cooled. Heat generation during buffing is considerably reduced by the application of the liquid. Smearing of glue emerging from the joint is avoided. The edge banding radius is wet buffed with the special cleaning agent LP163/93?. As a consequence, heating of the thermoplastic material is notably reduced, and a smearing of the plastic is prevented. Moreover, the radius is polished to match the surface sheen. Glue residue no longer adheres to the buffing wheels.

Result: An absolutely clean board edge!

This result can only be obtained when the buffing wheels is used across its entire width without oscillation. The buffing disc must be used with an inclination in relation to the workpiece of 3?, without oscillation and applying only slight pressure.

Rotational direction should be in synchronous run to reduce heat generation.

Consumption per fine nozzle: under 1 liter for 5000 running meters. The electronically controlled cleaning agent spraying unit only requires a compressed air connection of 3 bar and a 230/24 V socket.

This unit is used to spray the cleaning agent LP163/93? on the top and bottom surface of the board edge, as well as the edgeband. The release agent applied at the machine infeed side and the loose glue residue are removed by the application of the cleaning agent and subsequent buffing.

Furthermore, the glue joint and the edge banding are cooled. Heat generation during buffing is considerably reduced by the application of the liquid. Smearing of glue emerging from the joint is avoided. The edge banding radius is wet buffed with the special cleaning agent LP163/93?. As a consequence, heating of the thermoplastic material is notably reduced, and a smearing of the plastic is prevented. Moreover, the radius is polished to match the surface sheen. Glue residue no longer adheres to the buffing wheels.

Result: An absolutely clean board edge!

This result can only be obtained when the buffing wheels is used across its entire width without oscillation. The buffing disc must be used with an inclination in relation to the workpiece of 3?, without oscillation and applying only slight pressure.

Rotational direction should be in synchronous run to reduce heat generation.

Consumption per fine nozzle: under 1 liter for 5000 running meters. The electronically controlled cleaning agent spraying unit only requires a compressed air connection of 3 bar and a 230/24 V socket.

Additional information

| Model Number | Cleaning Agent LP 163/93? |

|---|---|

| Usage | NA |

| Dimension(L*W*H) | NA |

| Net weight | NA |

| Material | NA |

| Load capacity/Life Cycle | NA |

| Power(W) | NA |

| Thickness | NA |

| Voltage | NA |

| Speed | NA |

| Delivery Detail | Delivered and installed by manufacturer. Cost on actuals. |

Brand

Riepe

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.