In stock

Upstream of the formatting unit, an ultra-thin coat of the release agent LPZ/II? is applied to the top and bottom surface of the workpieces (edge area) by means of our electronically controlled release agent spraying unit. This prevents squeezed out glue from adhering to the workpiece.

An ultra-thin application of our release agent in the edge area (consumption per nozzle under 1 liter per 5000 running meters) guarantees a perfect result.

The electronically controlled release agent spraying unit only requires a 3 bar compressed air connection and a 230/24V outlet.

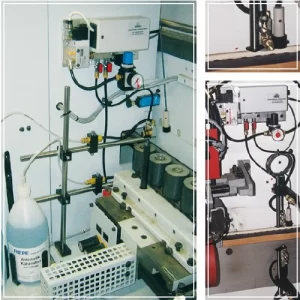

Our special release agents are adapted to all commercially available glues. In illustration 1 you can see the installation of the spraying unit inside the cladding directly before the formatting unit, with the relevant fixing bracket. Our fine nozzles are not sensitive to dust and can therefore be fitted directly in front of the tooling.

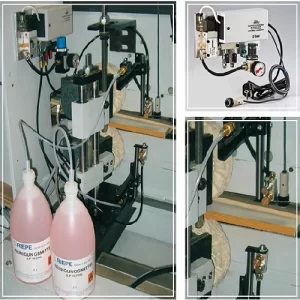

In illustration 2 you can see the installation outside the cladding, prior to formatting, with the appropriate bracket. On the opposite side of the machine the unit is connected to the longitudinal fence with the appropriate bracket. We also have an assortment of special fixings to meet your needs.

For post- or softforming machines our high heat resistant release agent TH97? is used. This special release agent can pass without problem through hot zones without losing its effectiveness.

Upstream of the formatting unit, an ultra-thin coat of the release agent LPZ/II? is applied to the top and bottom surface of the workpieces (edge area) by means of our electronically controlled release agent spraying unit. This prevents squeezed out glue from adhering to the workpiece.

An ultra-thin application of our release agent in the edge area (consumption per nozzle under 1 liter per 5000 running meters) guarantees a perfect result.

The electronically controlled release agent spraying unit only requires a 3 bar compressed air connection and a 230/24V outlet.

Our special release agents are adapted to all commercially available glues. In illustration 1 you can see the installation of the spraying unit inside the cladding directly before the formatting unit, with the relevant fixing bracket. Our fine nozzles are not sensitive to dust and can therefore be fitted directly in front of the tooling.

In illustration 2 you can see the installation outside the cladding, prior to formatting, with the appropriate bracket. On the opposite side of the machine the unit is connected to the longitudinal fence with the appropriate bracket. We also have an assortment of special fixings to meet your needs.

For post- or softforming machines our high heat resistant release agent TH97? is used. This special release agent can pass without problem through hot zones without losing its effectiveness.

Additional information

| Model Number | Release Agent LP Z/II ? / Release Agent TH 97? -highly heat resistant |

|---|---|

| Usage | NA |

| Dimension(L*W*H) | NA |

| Net weight | NA |

| Material | NA |

| Load capacity/Life Cycle | NA |

| Power(W) | NA |

| Thickness | NA |

| Voltage | NA |

| Speed | NA |

| Delivery Detail | Delivered and installed by manufacturer. Cost on actuals. |

Brand

Riepe

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.