SCM Automatic Edgebander Me 20-Ce R001801

FEATURES:

– Machine frame made of steel, single-block base to guarantee an excellent support for the operating units

– Friction-free worktable with n.3 rollers

– Panel-to-use in any working conditions

– Panel feed by means of a top feeder with high-adherence toothed belt with steel cables inside

– Feeder manual lifting with positioning of all operating units synchronised with the feeder and based on the panel

height

– Numeric readout of the selected panel

– Telescopic front support with rollers for all the machine length

– Anodized aluminium outfeed fence

– Glue smokes specific exhaust outlet; centralized exhaust outlet of the other dusts

BASIC MACHINE UNITS:

GLUE POT UNIT, EDGE LOADING AND PRESSING SYSTEM Complete with:

– Hot melt glue with quick heat up system and internally teflon coated to allow an easy glue replacement

– Glue application on the panel by means of glue spreading roller

– Temperature adjustment of the applied glue integrated in the PLC control

– Device for automatic recovery of unused glue

– Automatic edge loading system for rolled edges with shear device for 2 mm max. thickness edges

– Coil holder plate, 730 mm diameter

– Pressing unit with n. 2 edge pressure rollers: one in steel and the second rubber coated

– Adjustable infeed fence with numeric readout of the edge thickness

– Automatic lowering of the glue pot temperature after a temporary machine non-use

END CUTTING UNIT

End cutting unit for the cut at 90 deg. on the leading and trailing edges of the panel. Possibility to exclude the unit through PLC.

SUPERPOSED TRIMMING UNIT

– Equipped with vertical copying pads for an accurate positioning of tools with reference to the cutting point.

– The unit is provided with 72 mm diameter, combined cutters: the radius part of the cutter is used to trim 2 mm radius edges and chamfered thin edges. The straight part of the cutter is used for the trimming of edges in wood up to 5 mm. Changing from radius edge to edge in wood is done easily moving the cutters axially. The edge thickness is shown by 2 numeric readouts.

TECHNICAL DATA:

– Worktable dimensions [mm] : 1950 x 180

– Worktable height [mm] : 904

– Thickness of rolled edges [mm] : 0,4 – 2

– Max. thickness of edges in strips [mm] : 5

– Min. – max. working height [mm] : 12 – 50

– Min. panel length/width with rolled edges [mm] : 180/65

– Min. panel length (frontal end cutting only) [mm] : 120

– Feed motor power S1 [kW] : 0,25

– Feed speed [m/min] : 6

– Pneumatic operating pressure [bar] : 6,5

– Operating temperature [deg.] : 190

– Exhaust outlet diameter (base) [mm] : 120

– Exhaust outlet diameter (glue pot) [mm] : 60

GLUE POT UNIT:

– Motor power S1 [kW] : 0,18

– Glue capacity [kg] : 0,5

TRIMMING UNIT:

– Motor power S1 [kW] : 0,55

– Widia cutters : Dia. 75 mm Z4

– Cutters rotation speed [rpm] : 12.000

SAFETY/PROTECTIONS

– Safety enclosure

– Electrical cabinet with PLC, padlockable main switch and overload protection

– Emergency pushbutton

Additional information

| Model Number | SKU : OLIMPIC-K560(R)(R052701) |

|---|---|

| Usage | SCM Automatic Single Sided Automatic Edgebander |

| Dimension(L*W*H) | NA |

| Net weight | NA |

| Material | Heavy duty frame structure and strong supports assure perfect stability |

| Load capacity/Life Cycle | [kg] : 1, 5 |

| Power(W) | NA |

| Thickness | 8 to 60, 0, 4 – 6, 0, 4 – 3 |

| Delivery Detail | Delivered and installed by manufacturer. Cost on actuals. |

Brand

Caple

-

₹1,068,750.00

₹1,125,000.00SCM Thicknessing Planer with Tersa Cutter Block

₹1,068,750.00₹1,125,000.00 -

-

₹30,173.00

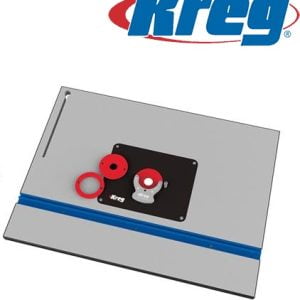

Kreg Precision Router Table Top PRS1025

₹30,173.00 -

₹3,170,625.00

₹3,337,500.00Mas MZB73216J Six-head Thru-feed Boring Machine MZB73216J

₹3,170,625.00₹3,337,500.00 -

₹134,128.00

₹160,953.00Festool Portable Router OF-2200

₹134,128.00₹160,953.00

Reviews

There are no reviews yet.