SCM Automatic Single Sided Automatic Edgebander OLIMPIC-K560 TER2-40

MACHINE & FEATURES:

– olimpic k 560 composition T-ER2 (40)

– Feed Track

– Control Unit 7″ Touch Screen

– “RT-V” pre-milling unit

– “VC-S4.1” gluing unit

– “K/SEL” end cutting unit

– “R-K” trimming unit

– “ROUND X” Rounding unit

– “RAS/K” edge scraping unit

– Nesting copying device kit

– AAR anti-adhesive unit

– Spray-mist device for edge finishing

– Infrared ceramic lamp

– iGLUE kit for gluing unit

– SGP glue pot with manual dosing in substitution of the standard one

– RC-N glue scraping unit

– SP-V brushing unit

TECHNICAL SPECIFICATION:

– Variable track feed speed [m/min] : 12 to 18

– Panel thickness [mm] : 8 to 60

– Thickness of edges in strips [mm] : 0,4 – 6

– Thickness of rolled edges [mm] : 0,4 – 3

– Max. section of rolled edges [mm2] : 135

– Coil-holder plate diameter [mm] : 780

– Distance between two successive panels [mm] : 600

– Minimum panel length (100 mm min. width) [mm] : 140

– Min. length of edge in rolls [mm] : 180

– Min. length of edge in strips [mm] : 220

– Min. panel width (210 mm min. length) [mm] : 95 (60)*

– * (60mm with unit adjustment modification)

– Opening for panel support roller [mm] : 560

– Worktable height [mm] : 900

“RT-V” pre-milling unit

– Max. removal [mm2] : 55

– Max thickness removal [mm] : 3

– Panel thickness [mm] : 8 – 45 (60**)

– Motors power [kW] : 1,5

– Tool diameter [mm] : 100

– Tool height [mm] : 49

– Tool rotating speed [rpm] : 9000

– ** with H=”64mm” tools)

“VC-S4.1” gluing unit

– Installed power [kW] : 3

– Heating time [min] : 12

– Glue pot capacity [Kg] : 1,5

“K/SEL” end cutting unit

– Motors power [kW] : 0,35

– Max. speed of blades [rpm] : 12000

“R-K” trimming unit

– Motors power [kW] : 0,55

– Speed of cutters [rpm] : 12000

– Minimum panel thickness with radius [mm] : 12

– Exceeding material to the panel thickness [mm] : 2+2

– Vertical/front copying devices : disc/pad

– Tool radius [mm] : 2

“ROUND X” Rounding unit

– Motor power [kW] : 0,35

– Speed of cutters [rpm] : 12000

– Edge thickness [mm] : 0,4 – 3

– Panel thickness – with a straight angle [mm] : 10 to 50

– Panel thickness – with a shaped angle (according to the profile) [mm] : 10-30/40

– Min. panel length [mm] : 140

– Min. panel width [mm] : 100

– Max. working speed during rounding operation [m/min] : 12

– Max. working speed during only trimming operation [m/min] : 18

– Distance between two successive panels [mm] : 600

– Vertical/front copying devices : disc/pad

– Knives radius [mm] : 2

“RAS/K” edge scraping unit

– Minimum Panel Thickness [mm] : 12

– Vertical/front copying devices : disc/pad

– Tool radius [mm] : 2

“SP-V” brushing unit

– Motors power: 0,13 kW

– Speed of cutters: 1.400 rpm

GENERAL FEATURES

– Automatic single-sided edge bander for the edge gluing with hot melt glue on straight panels, on the four panel sides,

finishing and rounding-off of the panel corners

– Base made of curved and welded steel plates to ensure a vibration free, highly rigid structure. Openings with

shoots for the removal of shavings to the floor that are not collected by the dust extraction.

– Top presser made of curved and welded steel plates and supported with steel columns. It provides a vibration free

structure on which the operating groups are located.

– Two rows of high-adherence rubber panel pressure wheels on the track and mounted on bearings. An enclosure

covers the wheels.

– Manual adjustment of presser at the machine’s infeed with positioning numerical readout

– Top operating groups fixed to the presser or mechanically connected on to it to allow the automatic positioning

according to the panel thickness. Lower groups fixed to the horizontal beam for a precise reference with respect to

the panel.

– All high frequency motors are equipped with static inverter.

– Safety enclosure on the entire length of the machine with poly-carbonate windows for the groups visualisation during

machining.

– 2 doors for the access to the operating groups; the first one with the only electric interlocking for the gluing unit and

the second one with electro-mechanical interlocking for the remaining groups.

– Exhaust outlets for the operating groups positioned on the top side of the safety enclosure

– Mobile control panel at machine infeed for an easy use from the operator”s working position

– Electrical cabinet in conformity with the current safety regulations.

– Electrical component positioned inside the base with door that allow an easy access in case of any maintenance

operations.

Additional information

| Model Number | SKU : OLIMPIC-K560(TER2-40) |

|---|---|

| Usage | SCM Automatic Single Sided Automatic Edgebander OLIMPIC-K560 TER2-40 |

| Dimension(L*W*H) | 140×95 (60)x900 |

| Net weight | NA |

| Material | Heavy duty frame structure and strong supports assure perfect stability |

| Load capacity/Life Cycle | [Kg] : 1, 5 |

| Power(W) | [kW] : 3, [kW] : 0, 35, [kW] : 0, 55, [kW] : 0, 35, 0, 13 kW, 1, 5 |

| Thickness | NA |

| Delivery Detail | Delivered and installed by manufacturer. Cost on actuals. |

Brand

Caple

-

₹1,246,875.00

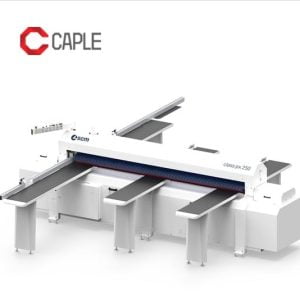

₹1,312,500.00SCM Horizontal Beam Saw – CLASS-PX250

₹1,246,875.00₹1,312,500.00 -

₹3,740,625.00

₹3,937,500.00SCM Compact Automatic Edgebander

₹3,740,625.00₹3,937,500.00 -

₹2,285,938.00

₹2,406,250.00Mas MZ73216DJ Six Head Boring Machine 15KW

₹2,285,938.00₹2,406,250.00 -

Reviews

There are no reviews yet.