Shreepal

-

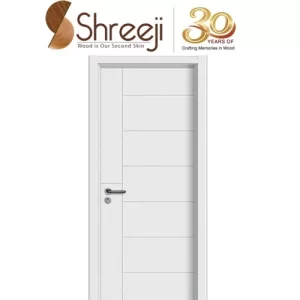

Shreeji Flush Door

Welcome to Shreeji, India’s Leading Flush Door Manufacturer

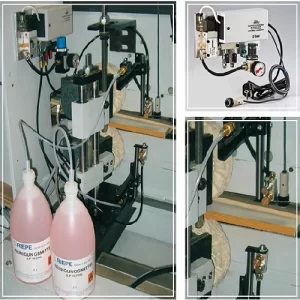

Your one-stop veneer flush door & laminate flush door manufacturer to help you create the space of your dreams. We?ve an extensive selection of doors that stand the test of time. These doors are of the highest quality and offer excellent resistance to heat, noise, dust, and water.Resplendent in their beauty, Shreeji?s flush doors are a rare combination of elegance and strength. These doors are not only designed to be visually appealing but match the aesthetics of the said properties? exteriors and interiors too.Our flush doors feature a solid and blockboard core, cross band, and veneer faces on either side. We strengthen timber with vacuum pressed chemical treatment as per IS:10013 and IS: 401. The moisture is treated through the seasoning process in an automatic kiln plant as per IS: 1144. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client requirement.

TYPE : (A) COMMERCIAL ? With face veneers from selected commercial hardwood.

TYPE : (B) DECORATIVE ? With one or both side face veneers from decorative timber like Teak, Wenge, Sapeli / varieties of lamination and decorative skins.

THICKNESS : 30, 32, 35, 38, 40, 45, 50 & 55 mm in double or single leaf construction.

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particleboard

? Honeycomb coreSALIENT FEATURES

Hot Pressed at high temperatures to ensure consistent performance for a long period of time

Calibrated Shutters

Termite Borer Proof

Offering light, imported Gurjan Face Veneer

Core drying for moisture. Full thickening Core

Manufactured as per IS 2202

Moisture-free Kiln Dry Seasoned Materials Used -

Shreeji Laminate Door LD-25

Welcome to the house of Shreeji, the greatest Laminated Doors Manufacturer in India. A name that builders, remodelers, and industry leaders choose when creating spaces of distinction. Combining the aesthetics of a natural wood grain and a fine laminate finish, the realistic texture of Shreeji?s laminate doors feels like real wood. Pre-finished to excellence and ready to install, Shreeji?s laminated doors bestow any property with beauty and practicality. Lamination is a process of pasting a laminated sheet with heat and pressure. It offers the ply of the material beneath extended longevity. All the more, the substance used in this process enhances the features and durability of the door. Hence, these doors are lightweight, easy to maintain, and completely washable.

Our laminated doors feature a blockboard core with the cross band, face veneer, and lamination, which are bonded with the Hot Press Process by using Urea Formaldehyde Resin with REBA for Boiling Water Resistant (B.W.R Grade) & Phenol formaldehyde Resin for 100% Boiling Water Proof (B.W.P. Grade). Rendered by us in user-defined specifications, they are always in high demand. They offer outstanding resistance against moisture and termite.

Shreeji?s doors undergo the process of lamination with excellent mechanical pressure and bonding against the time-consuming manual process on site. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client?s requirement.

THICKNESS : 30, 32, 35, 38, 40, 45mm

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particle board

? Honeycomb coreSALIENT FEATURES

Range of decorative laminate used to match interiors

Crafted to be dimensionally stable

Shock Resistant & Termite Borer Proof

Features BWR Grade or BWP Grade Plywood that offers much better resistance to water

Moisture-free kiln dry seasoned materials used

Available in 0.8mm or 1mm thick high pressure laminate

Satisfied Criteria of bonding of laminate ensure consistent performance for a long period of time

Accuracy in size & thickness

Calibrated Shutters -

Shreeji Laminate Door LD-30

Welcome to the house of Shreeji, the greatest Laminated Doors Manufacturer in India. A name that builders, remodelers, and industry leaders choose when creating spaces of distinction. Combining the aesthetics of a natural wood grain and a fine laminate finish, the realistic texture of Shreeji?s laminate doors feels like real wood. Pre-finished to excellence and ready to install, Shreeji?s laminated doors bestow any property with beauty and practicality. Lamination is a process of pasting a laminated sheet with heat and pressure. It offers the ply of the material beneath extended longevity. All the more, the substance used in this process enhances the features and durability of the door. Hence, these doors are lightweight, easy to maintain, and completely washable.

Our laminated doors feature a blockboard core with the cross band, face veneer, and lamination, which are bonded with the Hot Press Process by using Urea Formaldehyde Resin with REBA for Boiling Water Resistant (B.W.R Grade) & Phenol formaldehyde Resin for 100% Boiling Water Proof (B.W.P. Grade). Rendered by us in user-defined specifications, they are always in high demand. They offer outstanding resistance against moisture and termite.

Shreeji?s doors undergo the process of lamination with excellent mechanical pressure and bonding against the time-consuming manual process on site. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client?s requirement.

THICKNESS : 30, 32, 35, 38, 40, 45mm

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particle board

? Honeycomb coreSALIENT FEATURES

Range of decorative laminate used to match interiors

Crafted to be dimensionally stable

Shock Resistant & Termite Borer Proof

Features BWR Grade or BWP Grade Plywood that offers much better resistance to water

Moisture-free kiln dry seasoned materials used

Available in 0.8mm or 1mm thick high pressure laminate

Satisfied Criteria of bonding of laminate ensure consistent performance for a long period of time

Accuracy in size & thickness

Calibrated Shutters -

Shreeji Laminate Door LD-6

Welcome to the house of Shreeji, the greatest Laminated Doors Manufacturer in India. A name that builders, remodelers, and industry leaders choose when creating spaces of distinction. Combining the aesthetics of a natural wood grain and a fine laminate finish, the realistic texture of Shreeji?s laminate doors feels like real wood. Pre-finished to excellence and ready to install, Shreeji?s laminated doors bestow any property with beauty and practicality. Lamination is a process of pasting a laminated sheet with heat and pressure. It offers the ply of the material beneath extended longevity. All the more, the substance used in this process enhances the features and durability of the door. Hence, these doors are lightweight, easy to maintain, and completely washable.

Our laminated doors feature a blockboard core with the cross band, face veneer, and lamination, which are bonded with the Hot Press Process by using Urea Formaldehyde Resin with REBA for Boiling Water Resistant (B.W.R Grade) & Phenol formaldehyde Resin for 100% Boiling Water Proof (B.W.P. Grade). Rendered by us in user-defined specifications, they are always in high demand. They offer outstanding resistance against moisture and termite.

Shreeji?s doors undergo the process of lamination with excellent mechanical pressure and bonding against the time-consuming manual process on site. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client?s requirement.

THICKNESS : 30, 32, 35, 38, 40, 45mm

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particle board

? Honeycomb coreSALIENT FEATURES

Range of decorative laminate used to match interiors

Crafted to be dimensionally stable

Shock Resistant & Termite Borer Proof

Features BWR Grade or BWP Grade Plywood that offers much better resistance to water

Moisture-free kiln dry seasoned materials used

Available in 0.8mm or 1mm thick high pressure laminate

Satisfied Criteria of bonding of laminate ensure consistent performance for a long period of time

Accuracy in size & thickness

Calibrated Shutters -

Shreeji Laminate Door LD-60

Welcome to the house of Shreeji, the greatest Laminated Doors Manufacturer in India. A name that builders, remodelers, and industry leaders choose when creating spaces of distinction. Combining the aesthetics of a natural wood grain and a fine laminate finish, the realistic texture of Shreeji?s laminate doors feels like real wood. Pre-finished to excellence and ready to install, Shreeji?s laminated doors bestow any property with beauty and practicality. Lamination is a process of pasting a laminated sheet with heat and pressure. It offers the ply of the material beneath extended longevity. All the more, the substance used in this process enhances the features and durability of the door. Hence, these doors are lightweight, easy to maintain, and completely washable.

Our laminated doors feature a blockboard core with the cross band, face veneer, and lamination, which are bonded with the Hot Press Process by using Urea Formaldehyde Resin with REBA for Boiling Water Resistant (B.W.R Grade) & Phenol formaldehyde Resin for 100% Boiling Water Proof (B.W.P. Grade). Rendered by us in user-defined specifications, they are always in high demand. They offer outstanding resistance against moisture and termite.

Shreeji?s doors undergo the process of lamination with excellent mechanical pressure and bonding against the time-consuming manual process on site. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client?s requirement.

THICKNESS : 30, 32, 35, 38, 40, 45mm

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particle board

? Honeycomb coreSALIENT FEATURES

Range of decorative laminate used to match interiors

Crafted to be dimensionally stable

Shock Resistant & Termite Borer Proof

Features BWR Grade or BWP Grade Plywood that offers much better resistance to water

Moisture-free kiln dry seasoned materials used

Available in 0.8mm or 1mm thick high pressure laminate

Satisfied Criteria of bonding of laminate ensure consistent performance for a long period of time

Accuracy in size & thickness

Calibrated Shutters -

Shreeji Laminate Door LD-66

Welcome to the house of Shreeji, the greatest Laminated Doors Manufacturer in India. A name that builders, remodelers, and industry leaders choose when creating spaces of distinction. Combining the aesthetics of a natural wood grain and a fine laminate finish, the realistic texture of Shreeji?s laminate doors feels like real wood. Pre-finished to excellence and ready to install, Shreeji?s laminated doors bestow any property with beauty and practicality. Lamination is a process of pasting a laminated sheet with heat and pressure. It offers the ply of the material beneath extended longevity. All the more, the substance used in this process enhances the features and durability of the door. Hence, these doors are lightweight, easy to maintain, and completely washable.

Our laminated doors feature a blockboard core with the cross band, face veneer, and lamination, which are bonded with the Hot Press Process by using Urea Formaldehyde Resin with REBA for Boiling Water Resistant (B.W.R Grade) & Phenol formaldehyde Resin for 100% Boiling Water Proof (B.W.P. Grade). Rendered by us in user-defined specifications, they are always in high demand. They offer outstanding resistance against moisture and termite.

Shreeji?s doors undergo the process of lamination with excellent mechanical pressure and bonding against the time-consuming manual process on site. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client?s requirement.

THICKNESS : 30, 32, 35, 38, 40, 45mm

SIZE : Supplied in Standard Size as per ISI or as per the requirements.

CORE OPTIONS :

? Timber core

? Particle board

? Honeycomb coreSALIENT FEATURES

Range of decorative laminate used to match interiors

Crafted to be dimensionally stable

Shock Resistant & Termite Borer Proof

Features BWR Grade or BWP Grade Plywood that offers much better resistance to water

Moisture-free kiln dry seasoned materials used

Available in 0.8mm or 1mm thick high pressure laminate

Satisfied Criteria of bonding of laminate ensure consistent performance for a long period of time

Accuracy in size & thickness

Calibrated Shutters -

Shreeji Skin Moulded Door 2 Panel

Shreeji, the greatest name in the HDF moulded door manufacturing industry in India, exhibits a range of moulded doors combining beauty & durability. HDF doors are bonded with Phenol Formaldehyde Synthetic Resin and available in a variety of textures and smooth finishes.

Shreeji?s Skin Moulded Doors are crafted with extreme finesse and precision. Manufactured using excellent HDF door skin bonded with high-grade resin, these doors meet superior-quality standards down to the last detail. We offer a variety of designs in this category. To live up to the expectations of high-quality standards, the raw material for in-fillers used are superior such as particle boards. Alternatively, moulding profile filled with semi-solid material of sawdust and resins is also used. These doors are chemically (vacuum) treated as per the requirements of IS : 401 and strongly bonded with high-grade PF glue. They are made using two layers: Honeycomb core and Particle Board. These are available in a variety of designs : 2 panels, 4 panels, 6 panels and even in decorative veneer finishes. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client requirement. THICKNESS : 30, 32, 35, 38, 40, 45, 50 & 55mm in double or single leaf construction. CORE OPTIONS :

Particle board

Honeycomb core

SALIENT FEATURES

Primered in White to allow you to paint in your desired colour

Features excellent screw holding capacity

Boasts an aesthetically beautiful look

Termite Borer Proof

Uses masonite skin -

Shreeji Skin Moulded Door 4 Panel

Shreeji, the greatest name in the HDF moulded door manufacturing industry in India, exhibits a range of moulded doors combining beauty & durability. HDF doors are bonded with Phenol Formaldehyde Synthetic Resin and available in a variety of textures and smooth finishes.

Shreeji?s Skin Moulded Doors are crafted with extreme finesse and precision. Manufactured using excellent HDF door skin bonded with high-grade resin, these doors meet superior-quality standards down to the last detail. We offer a variety of designs in this category. To live up to the expectations of high-quality standards, the raw material for in-fillers used are superior such as particle boards. Alternatively, moulding profile filled with semi-solid material of sawdust and resins is also used. These doors are chemically (vacuum) treated as per the requirements of IS : 401 and strongly bonded with high-grade PF glue. They are made using two layers: Honeycomb core and Particle Board. These are available in a variety of designs : 2 panels, 4 panels, 6 panels and even in decorative veneer finishes. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client requirement. THICKNESS : 30, 32, 35, 38, 40, 45, 50 & 55mm in double or single leaf construction. CORE OPTIONS :

Particle board

Honeycomb core

SALIENT FEATURES

Primered in White to allow you to paint in your desired colour

Features excellent screw holding capacity

Boasts an aesthetically beautiful look

Termite Borer Proof

Uses masonite skin -

Shreeji Skin Moulded Door 6 Panel

Shreeji, the greatest name in the HDF moulded door manufacturing industry in India, exhibits a range of moulded doors combining beauty & durability. HDF doors are bonded with Phenol Formaldehyde Synthetic Resin and available in a variety of textures and smooth finishes.

Shreeji?s Skin Moulded Doors are crafted with extreme finesse and precision. Manufactured using excellent HDF door skin bonded with high-grade resin, these doors meet superior-quality standards down to the last detail. We offer a variety of designs in this category. To live up to the expectations of high-quality standards, the raw material for in-fillers used are superior such as particle boards. Alternatively, moulding profile filled with semi-solid material of sawdust and resins is also used. These doors are chemically (vacuum) treated as per the requirements of IS : 401 and strongly bonded with high-grade PF glue. They are made using two layers: Honeycomb core and Particle Board. These are available in a variety of designs : 2 panels, 4 panels, 6 panels and even in decorative veneer finishes. Our range of doors, frames, and solutions can also be custom-designed by an architect as per their client requirement. THICKNESS : 30, 32, 35, 38, 40, 45, 50 & 55mm in double or single leaf construction. CORE OPTIONS :

Particle board

Honeycomb core

SALIENT FEATURES

Primered in White to allow you to paint in your desired colour

Features excellent screw holding capacity

Boasts an aesthetically beautiful look

Termite Borer Proof

Uses masonite skin